SpiTrex SWI (Switzerland)

+41 32 552 10 00

Girardet 29

2400 Le Locle,

Switzerland

Home | Locations | SpiTrex Switzerland | SpiTrex Switzerland Capabilities

Swiss Precision at Every Step

At SpiTrex SWI in Le Locle, Switzerland, we offer a fully integrated pathway for orthopedic manufacturing. From collaborative design through to final inspection and packaging, our capabilities reflect a commitment to innovation, precision and quality at every stage.

Explore each area of our operations below to learn how we bring your orthopedic solutions to life.

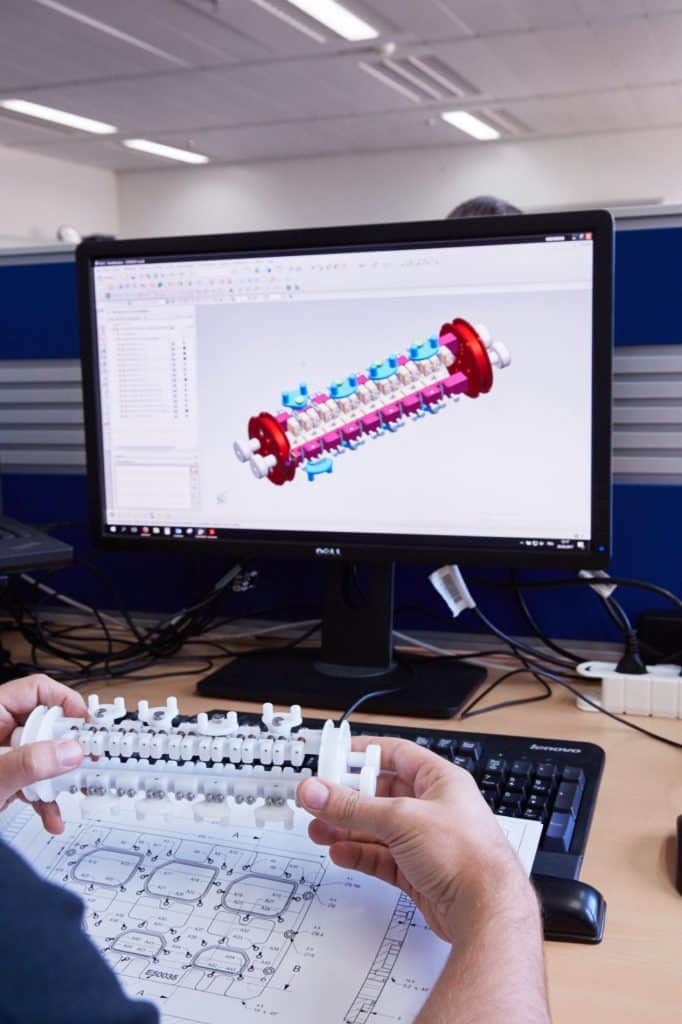

Co-Design & Engineering

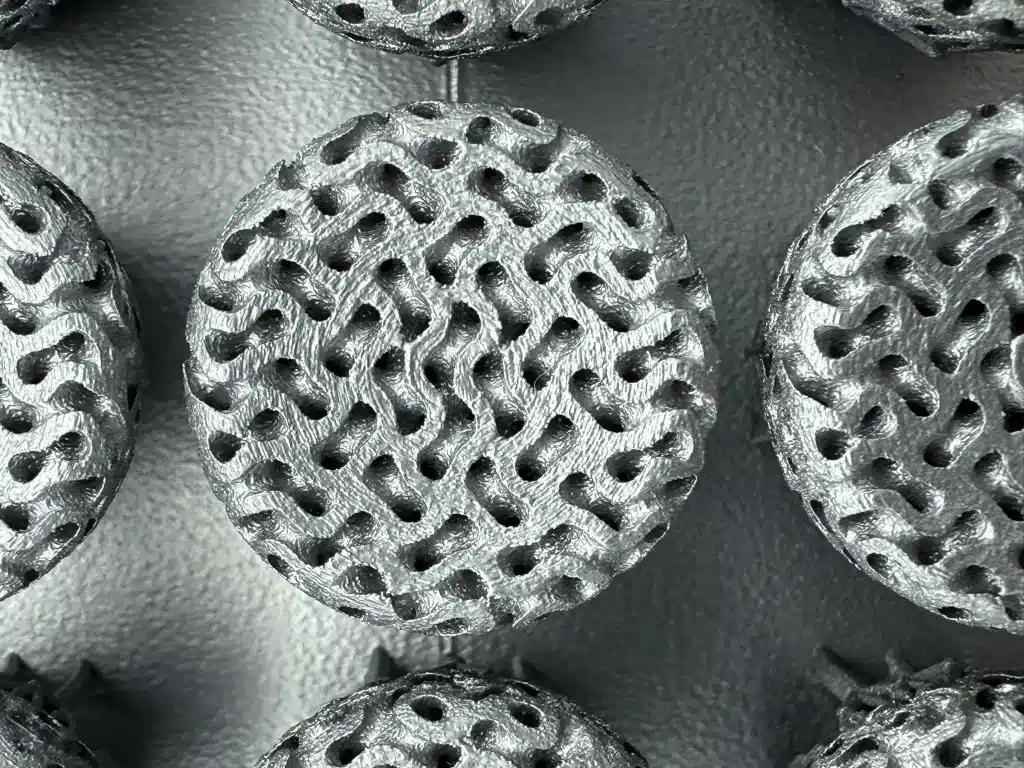

At SpiTrex SWI, we work closely with our partners to engineer custom solutions that meet the distinct challenges of each project. By integrating advanced CAD tools, titanium 3D printing (in partnership with SpiTrex 3D) and high-precision metrology, we optimize designs for manufacturability and performance. Together, we transform ideas into high-value medical products.

Machining Hall

Our machining hall is equipped with cutting-edge DMG CNC machines, operated by experienced technicians trained in high-tolerance medical device production. With the ability to manage small batches or large production runs, we provide fast turnaround without sacrificing accuracy. Each part undergoes rigorous process control to meet the industry’s most demanding standards. Our lineup includes Swiss turning centers for high-precision cylindrical work, as well as 3-axis and 5-axis milling machines capable of producing complex geometries with exceptional repeatability.

Finishing & Surface Treatment

Our finishing processes enhance both functionality and appearance. We offer precision polishing, deburring and blasting, along with validated implant cleaning and advanced color and Type II anodization. Our in-house passivation and laser marking capabilities ensure every component is safe, durable and traceable, meeting all regulatory and aesthetic requirements. We also offer thermocompression for specialized bonding and material fusion applications, delivering high-integrity results for medical device assemblies.

Quality Control

Our quality assurance process is anchored by automated systems and advanced metrology tools, including 3D CMM machines from Zeiss (Duramax and Contura), 2D scanning via Hommel and an integrated SPC inspection data recording system.

These systems allow real-time tracking of CTQ characteristics, immediate response to variances and total traceability. We also use COGNEX vision systems for part verification, measurement and counting.

Clean Room & Packaging

Our ISO 7-certified clean room supports fully integrated clean and pack services, offering both sterile and non-sterile packaging options to match your project’s needs. From blister and pouch formats to validated sealing and labeling, we manage the final stage of your product’s lifecycle with the same rigor applied throughout.

UHMWPE Thermocompression

At SpiTrex Switzerland, we have developed strong expertise in UHMWPE thermocompression without the use of release agents, ensuring clean, reliable, and high-strength assemblies for orthopedic implants where mechanical performance is critical. Our process is fully compatible with metal additive manufactured (3D-printed) implants, precision-machined orthopedic components, and a wide range of joint prostheses, including shoulder and knee applications. By eliminating release agents, we significantly reduce contamination risks while achieving excellent mechanical strength and bearing surface quality. All UHMWPE materials conform to ISO 5834-2, and the process is fully validated for demanding orthopedic applications.